TECHNICAL STRENGTH

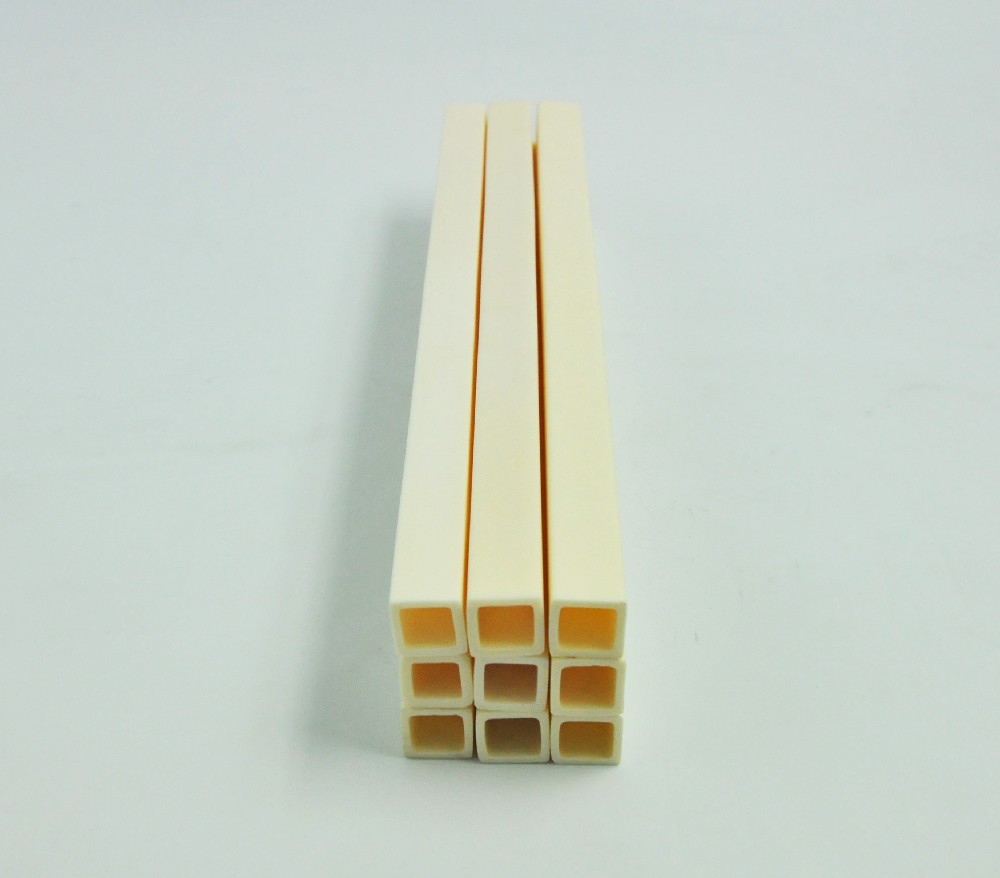

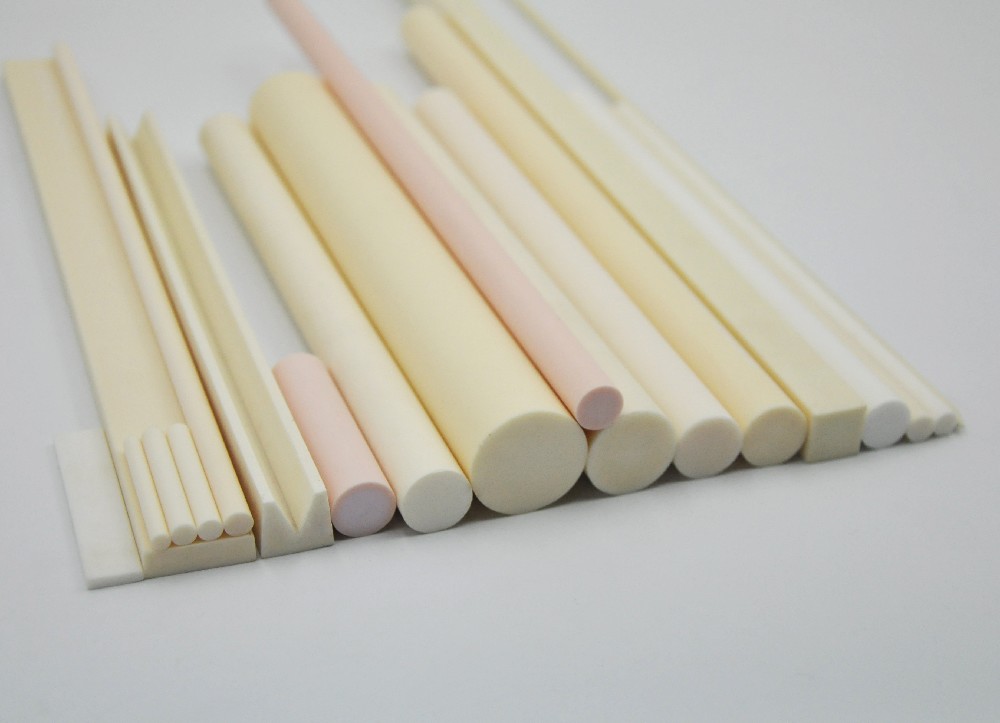

Production workshop 10 cubic volume six cities of 1800 degrees high temperature furnace, eight kiln 5-10 cubic volume of 1500 degrees, many sets of grinding equipment. Product production process with grouting molding, hot die casting molding, dry pressing molding, such as static pressure molding, extrusion molding, roll forming, note the condensed type. The main alumina ceramic, zirconia ceramic products, such as product involves the sagger, crucible, pipe, plate, ball and so on, all of them are for the customers to choose, we can customize products, to sample or to map processing, one-on-one service, according to the different environment and use methods to help customers selected the suitable material and optimize the product structure.

-

Congratulations to kosu Tuttle website success onl

Congratulations to kosu Tuttle website success online ?

-

Refractory industry association and the window of

On August 28, 2021 morning in refractory industry in hebei province association; deputy head jing-lo...

-

Tangshan kosu special ceramics manufacture co., LT

Tangshan kosu special ceramics manufacturing co., LTD., long-term procurement of alpha alumina, welcome the masses of manufacturer...

06-16

2022

>

Copyright:Tangshan Keshuo special ceramics manufacturing Co.,LtdTechnical Support:Tangshan chenglian e-commerce Co.,Ltd

Filing/License Number:冀ICP备14001106号

Back-stage Management

Follow our official account for more highlights.

Follow our official account for more highlights.